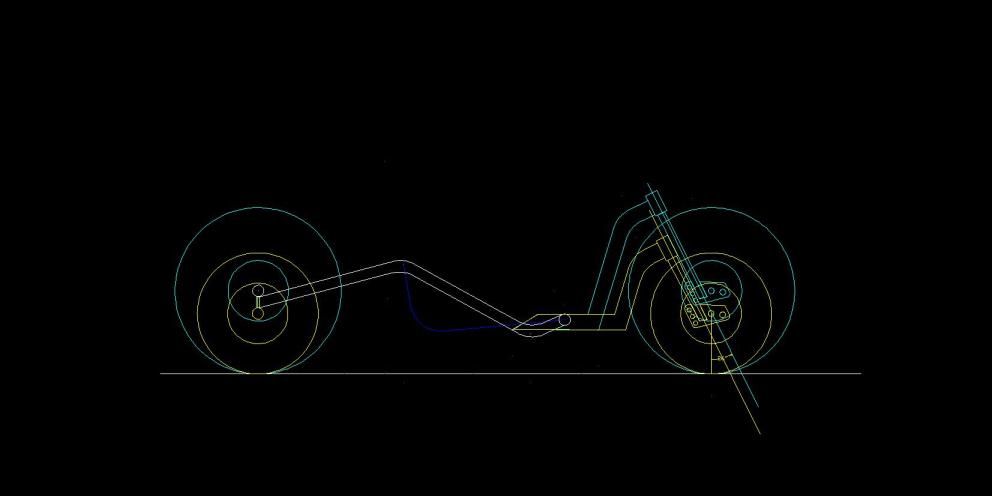

Hope to see you at WBB. You will get a better look at the buggy. I would appreciate more feedback then.

| Quote: |

| Quote: |

| Quote: |

| Quote: |

| Quote: |

nice one!

nice one!

Brilliant!

Brilliant! My wife helped me unload the 1000 lbs milling machine off the trailer but she gave me this funny look the whole time. I might

have to buy the neighbor's house soon and live there if I keep this up :evil:

My wife helped me unload the 1000 lbs milling machine off the trailer but she gave me this funny look the whole time. I might

have to buy the neighbor's house soon and live there if I keep this up :evil:

| Quote: |

buggy PORN :shocked2:

buggy PORN :shocked2:

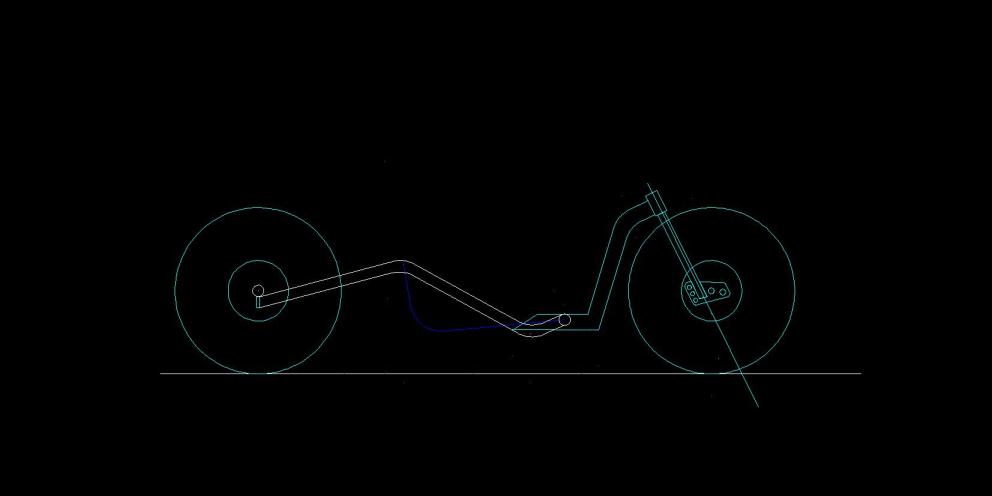

hehehe.. I'm still the

grasshopper at this welding stuff. That's why this is just a prototype of what I plan to build in the future. Yes, I cut the space to space my weld

apart so the heat does not bend the axle. I'm not really fond of the clamp type.

hehehe.. I'm still the

grasshopper at this welding stuff. That's why this is just a prototype of what I plan to build in the future. Yes, I cut the space to space my weld

apart so the heat does not bend the axle. I'm not really fond of the clamp type.

| Quote: |