OffAxis,

Nicely done. I'm way curious, as I'm thinking of following along in your footsteps. I used to be an automotive design engineer, I'm a decent TIG

welder, have tools and access to some decent tools, including high powered hydraulic tubing bender with complete set of mandrels. Unfortunately I'm

a kite cart newbee, and I don't know a soul around here who has a cart that I might try. I've still got a lot of kite control (learning) work to do.

At the same time somebody offered me up a set of 3 small trailer wheels (4 stud on 4" radius), with two hubs. A hub for the front runs around $47 for

sealed tapered bearing setup, from our friends in Azusa, CA.

Been looking closely at your content here. I'm really curious to know how those trail numbers work out for you.

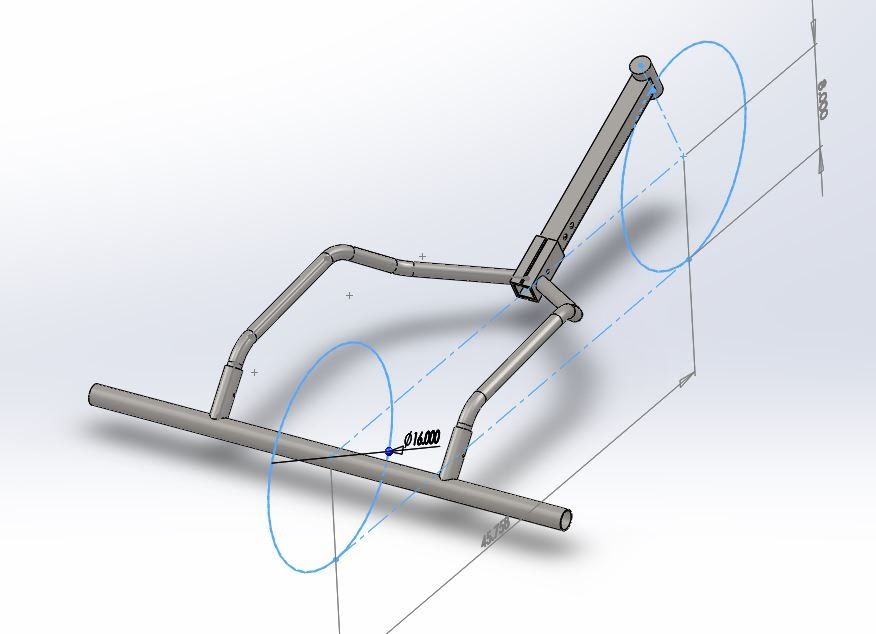

In fact I have one tool that might be of interest to you (and anybody else here). I spent a whole lot of time looking at custom bicycle and other

related frame designs. I rewrote software to do all sorts of tubing miter work. Its online and free, includes simple miters, decorative sleeving,

Seat Tube to Seat Stays joint, round to tapered, oval to round, engine exhaust collectors, airframe cluster joints, etc...

Hosted on my site, all my work, feel free to use. The software generates full size paper templates. Cut on the line, wrap the tube, use a felt tip

pen to mark the cut boundary, throw it into a vise and cut away. I've also included reference markings to make component lengths perfect.

Click here for the TubeNotcher software

Code is currently written in JavaScript, so it runs right in the browser, creates full size templates on paper (including large diameter tubing).

Nothing to download beyond Adobe Acrobat Reader.

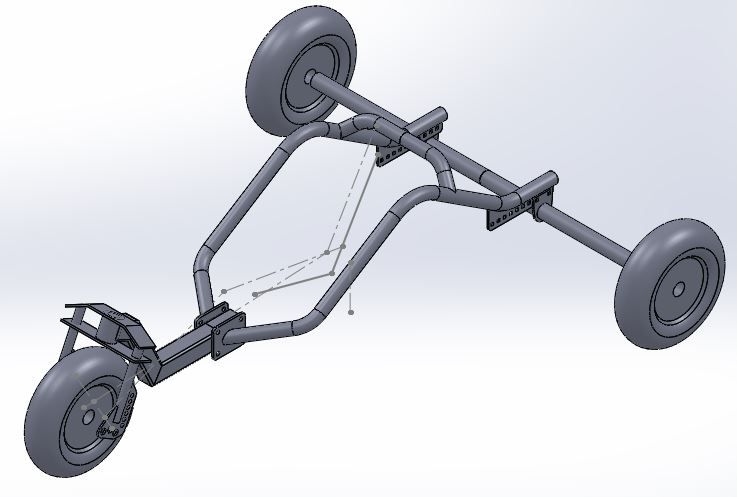

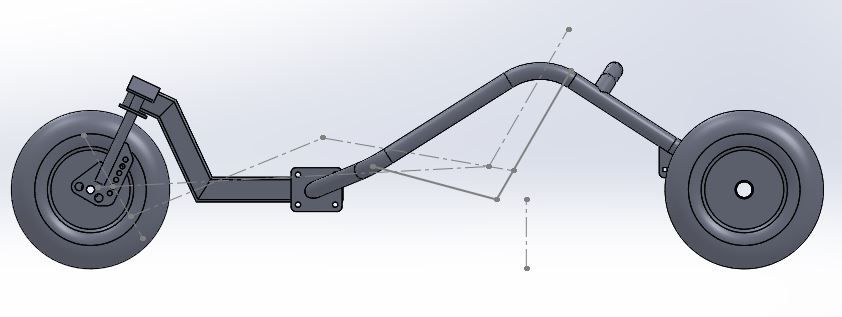

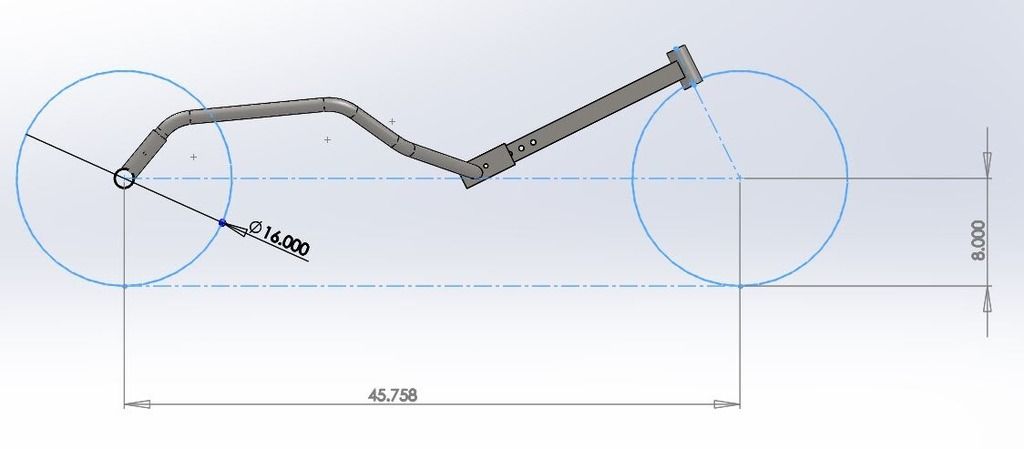

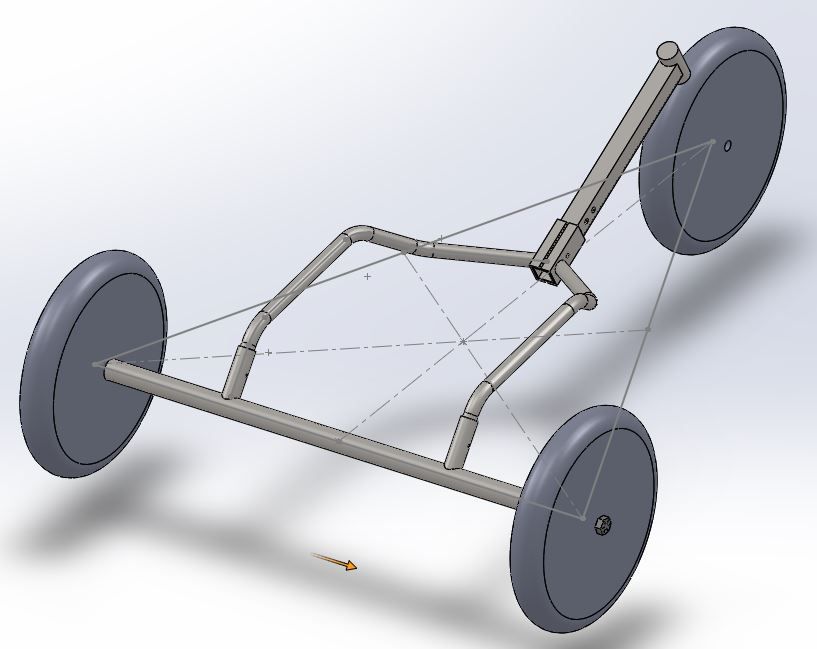

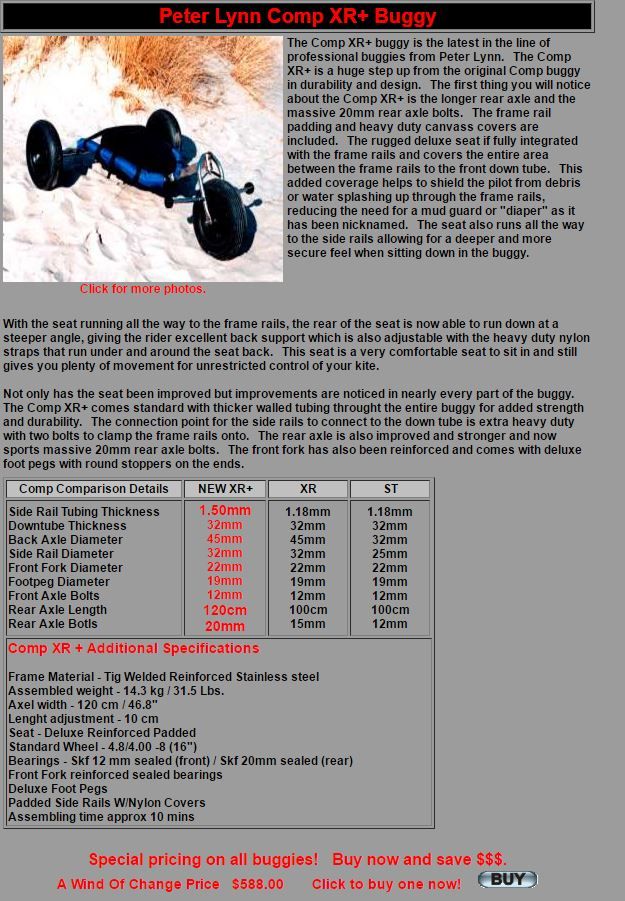

Possible to get a copy of your solidworks model in exchange? I suspect I will want less ground clearance than you, (I'm only on a dry lake bed, and

its way flat...) and I certainly have to accommodate my oddball little trailer wheels, but a model like yours would be a place to start.. I do have

some specific ideas on a different front fork design I'd like to try. If my request is out of bounds, no offense intended.

Many thanks for sharing the details you've already provided...

Zip

|

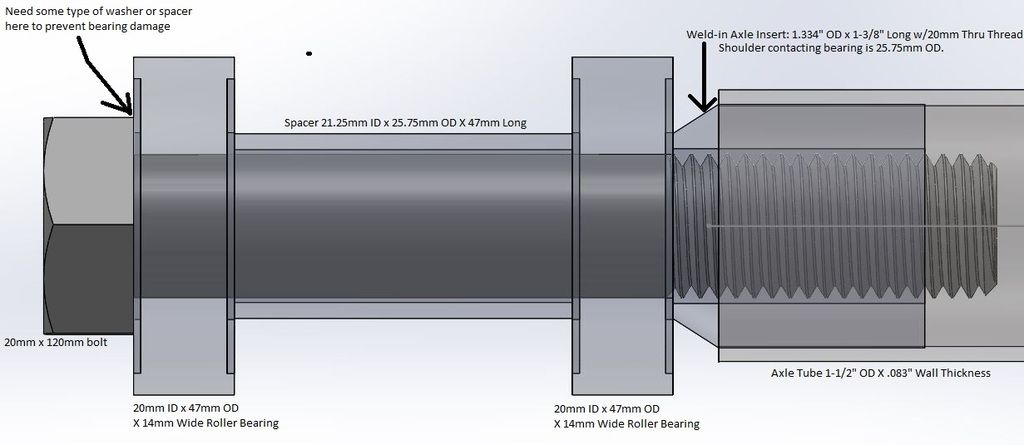

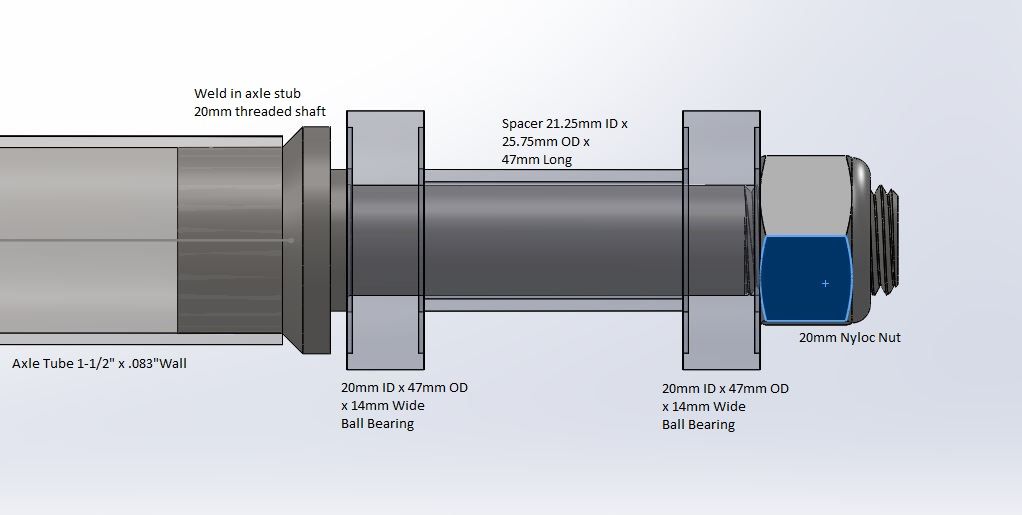

You are waaaayyyyy overthinking this. Sideloading isn't an issue.If you get

pulled sideways too hard , you just sideslip a bit. And in10 yrs.,I haven't heard of a bearing causing a wheel to come off.

You are waaaayyyyy overthinking this. Sideloading isn't an issue.If you get

pulled sideways too hard , you just sideslip a bit. And in10 yrs.,I haven't heard of a bearing causing a wheel to come off.

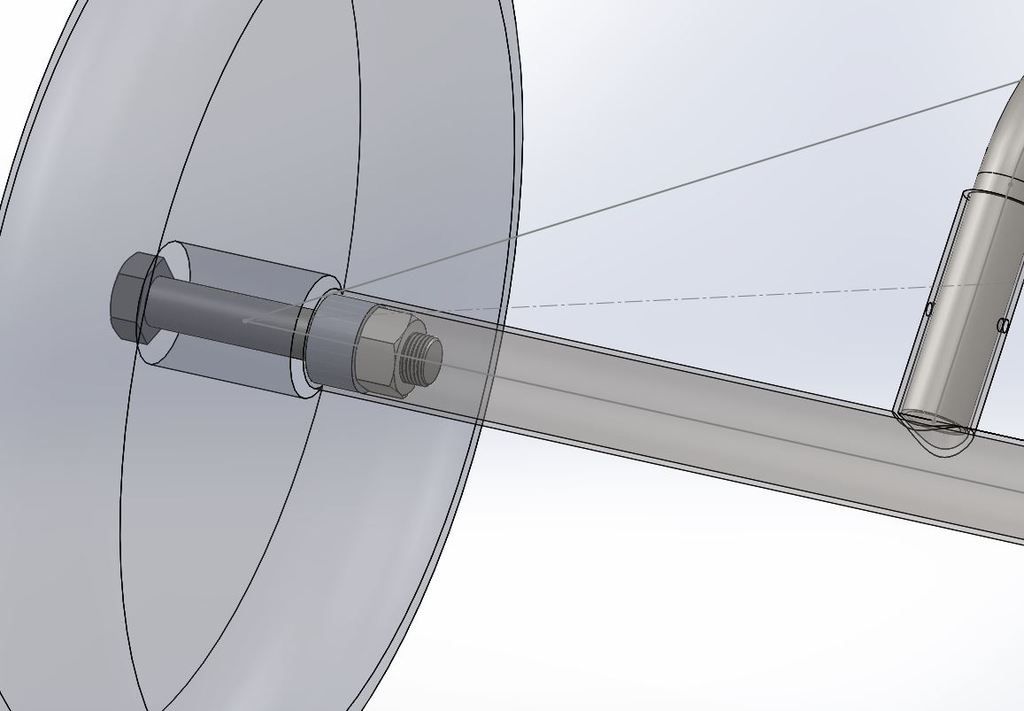

) No other metal, just the wheel and tire (and a little anti-seize on the 20mm

bolt).

) No other metal, just the wheel and tire (and a little anti-seize on the 20mm

bolt).

... Thanks! it sure feels faster!!! and it sure does hold me in when my

"Glorified beds sheets" get a little twitchy. I've redone so much of it that that I'm probably responsible for 80% of it myself... following Van's

model of course!

... Thanks! it sure feels faster!!! and it sure does hold me in when my

"Glorified beds sheets" get a little twitchy. I've redone so much of it that that I'm probably responsible for 80% of it myself... following Van's

model of course!

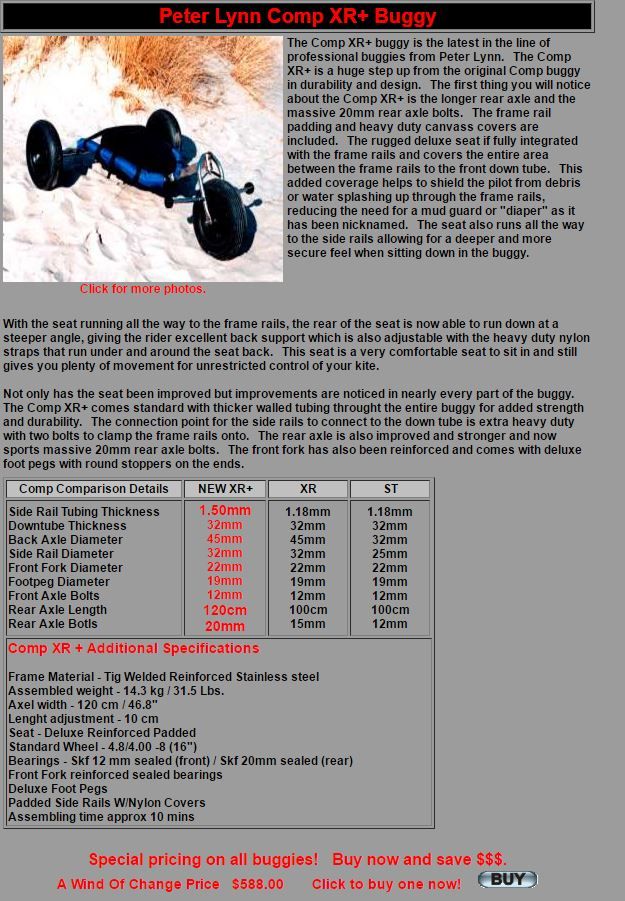

60 kph in a peter lynn is a bit of a brown pants moment, but 60 in a larger race buggy just feels good.

60 kph in a peter lynn is a bit of a brown pants moment, but 60 in a larger race buggy just feels good.

) can't give you that.

) can't give you that.