| Pages:

1

2

3 |

robinsonpr

Member

Posts: 351

Registered: 25-10-2014

Location: Stevenage UK

Member Is Offline

|

|

And thanks volock, I suspect you're right about the forces involved and a pin setup being the only sure fire fix. I'll take that as the last resort

if non of the other suggestions "stick".

And yeah it's all stainless. Don't fancy my chances of accurately drilling by hand though!

Rev 1.5 SLE

PL Pepper 1.5m, Twister III 3m

Flysurfer Peak I 6m, Peak II 12m

Ozone Access V6 6m, 4m incoming!

Arcs Venom 13m, Synergy 15m

LEIs Slingshot Rally 7m, 9, 12m

Kheo Flyer Landboard

PTW SuperBug II

Nobile NHP Carbon Split

|

|

|

PHREERIDER

Posting Freak

Posts: 5781

Registered: 13-2-2008

Location: SC

Member Is Offline

Mood: chilled....but ready to SAIL!

|

|

Quote: Originally posted by volock  | I'd think the main options/idea would be:

Sticking on removeable texture: ie Hockey grip tape (like used for wrapping the bottom end of your stick) or Skate Grip Tape

or Velcro

Spray on texture: ie glue / glue with sand in it / etc

Sanding to roughen the surface

Drilling holes for clevis pin setup

Personally with the forces involved, I'd be shocked if anything but the bottom option worked longterm. Were it me, I'd probably go with drilling small

holes, through the axle at 90 degress of each other, to get you the highest, medium and lowest orientation of the axle, and then one hole that will

line up properly with those straight through the axle clamps, and use a small clevis pin for holding it. It'd stop the rotation, and still leave some

of the benefits of the axle design. As I'd assume it's all stainless, while no holes is preferable, the small holes I don't think would expand the

corrosion risk much.

|

definitely drill and pin, ample size as well . one at favorite setting.

|

|

|

RedSky

Posting Freak

Posts: 1751

Registered: 7-9-2009

Member Is Offline

|

|

The hard stuff is stronger, withstanding the torsional forces without tearing but first try the Velcro as it was intended then try hook on hook.

Get down to homebase. They sell the wide stuff.

|

|

|

volock

Member

Posts: 425

Registered: 5-8-2013

Location: Dallas, TX

Member Is Offline

Mood: Choosing your new depower foil quiver is hard...

|

|

If drilling with a drill press, I'd say make sure to use a V-Block, worth it's weight in gold for drilling tubing. Not much experience off one for

drilling that stuff in something I'd care that much about, so I'll leave it to PopEye or one of the other experts around here to advise.

NAPKA US314 (Pi)

Stunt Kites: GoFlyAKite Parastunter 1.4m | Pacific Quest Mighty Bug 0.5m and 1.0m | Prism Flip Kite

Arcs: Peter Lynn Venom 19m

Depower Foils: Flysurfer Peak 12m, Peter Lynn Lynx (2015) 5m, 9m

FB Foils: HQ Beamer II 3.6m | Ozone LittleDevil 4.5m | Pansh Ace 5m, 7m | PKD Busta Soulfly 1.5m, 2.4m, Brooza II 7.5m | Prism Tensor 5m | Thunderwing

Parawings Set

LEIs: Cabrinha Convert SE 9m | Ocean Rodeo Prodigy 14.0m, Razor 12m, Storm 5.0m

Atomic Terrain Park Skis (w AT adapters for the wind dieing), Snowboard, 21" Isvidda Nordic Skates (NNN-BC and NIS bindings depending on the

pair),

Badfisher 11' SUP, Ocean Rodeo JT Pro 138cm

Landyachtz DH Race (Bear 852 Trucks), MBS Comp 95X

RB Swindler, Skorpion Skates

Sysmic S2 Dune Midi XL Buggy |

|

|

soliver

Posting Freak

Posts: 3913

Registered: 15-12-2011

Location: somewhere, far, far away

Member Is Offline

Mood: sleepy

|

|

I was thinking it wouldn't hurt to check in with Popeye... he may have a suggestion since he MADE the thing.

Hey, robinsonpr, post us up some detail pics of what the clamp looks like... not only am i curious, but it also may help us visualize a possible

solution.

I'm going to take a nap now

|

|

|

bigE123

Member

Posts: 442

Registered: 26-1-2012

Member Is Offline

|

|

That is one beast you have there!!  Not sure about packing the clamp I

think there is just too much force with the cantered axle ends, first thought is pin it, but drilling SS, may need a fabricator to do that for you.

Two holes in the axle would give you three positions high, low and a mid setting.

Blade V 4.9m & 8.5m VIP,Ozone Frenzy 11m, SS Flexifoil buggy, PL hybrid suspension buggy (PTW), MBS core 95.

homemade:

NPW 9b: 7m (Union Jack). NPW 9b HA 3m (Damien) and 10m (Jolly R). NPW21 3m, 5m (aka Zombie), 8m (Batman), 11.5m (NASA), NPW 21 HA 6.8m

The Hammers 5m, 7.2m & 12m

|

|

|

robinsonpr

Member

Posts: 351

Registered: 25-10-2014

Location: Stevenage UK

Member Is Offline

|

|

Popeye is out of the building game now. What a loss! I did get in touch with him about the slippage, he said wrap some gaffa tape around the axle

That's what it had when I got it from the previous owner. It was all worn and

chewed up but new stuff didn't help.

E you're gonna have to explain the 2 holes, 3 positions :puzzled:

I'll post a pic of the clamps later today.

Thanks all!

Rev 1.5 SLE

PL Pepper 1.5m, Twister III 3m

Flysurfer Peak I 6m, Peak II 12m

Ozone Access V6 6m, 4m incoming!

Arcs Venom 13m, Synergy 15m

LEIs Slingshot Rally 7m, 9, 12m

Kheo Flyer Landboard

PTW SuperBug II

Nobile NHP Carbon Split

|

|

|

robinsonpr

Member

Posts: 351

Registered: 25-10-2014

Location: Stevenage UK

Member Is Offline

|

|

Other alternative...just set the axle at it's lowest position and pull the seat straps up tighter so my ass isn't dragging on the ground. Simple!

But has the disadvantage of having to have the seat 2-3 inches higher, so losing the security of the super high side rails...

Rev 1.5 SLE

PL Pepper 1.5m, Twister III 3m

Flysurfer Peak I 6m, Peak II 12m

Ozone Access V6 6m, 4m incoming!

Arcs Venom 13m, Synergy 15m

LEIs Slingshot Rally 7m, 9, 12m

Kheo Flyer Landboard

PTW SuperBug II

Nobile NHP Carbon Split

|

|

|

bigE123

Member

Posts: 442

Registered: 26-1-2012

Member Is Offline

|

|

With the axle at it's highest, drill one hole through the clamp top to bottom through the axle as well. You can then rotate the axle 180 deg and you

now have two positions where you can put a pin through highest and lowest. Rotate the axle 90 deg, drill through the clamp hole and make another hole

in the axle, you now have a mid position as well....... simples :D

Blade V 4.9m & 8.5m VIP,Ozone Frenzy 11m, SS Flexifoil buggy, PL hybrid suspension buggy (PTW), MBS core 95.

homemade:

NPW 9b: 7m (Union Jack). NPW 9b HA 3m (Damien) and 10m (Jolly R). NPW21 3m, 5m (aka Zombie), 8m (Batman), 11.5m (NASA), NPW 21 HA 6.8m

The Hammers 5m, 7.2m & 12m

|

|

|

bigE123

Member

Posts: 442

Registered: 26-1-2012

Member Is Offline

|

|

Or just loose some weight lard @rse :D :D :D

Blade V 4.9m & 8.5m VIP,Ozone Frenzy 11m, SS Flexifoil buggy, PL hybrid suspension buggy (PTW), MBS core 95.

homemade:

NPW 9b: 7m (Union Jack). NPW 9b HA 3m (Damien) and 10m (Jolly R). NPW21 3m, 5m (aka Zombie), 8m (Batman), 11.5m (NASA), NPW 21 HA 6.8m

The Hammers 5m, 7.2m & 12m

|

|

|

robinsonpr

Member

Posts: 351

Registered: 25-10-2014

Location: Stevenage UK

Member Is Offline

|

|

Oh yeah :D :D

Rev 1.5 SLE

PL Pepper 1.5m, Twister III 3m

Flysurfer Peak I 6m, Peak II 12m

Ozone Access V6 6m, 4m incoming!

Arcs Venom 13m, Synergy 15m

LEIs Slingshot Rally 7m, 9, 12m

Kheo Flyer Landboard

PTW SuperBug II

Nobile NHP Carbon Split

|

|

|

robinsonpr

Member

Posts: 351

Registered: 25-10-2014

Location: Stevenage UK

Member Is Offline

|

|

Here's the rear axle clamps:

Rev 1.5 SLE

PL Pepper 1.5m, Twister III 3m

Flysurfer Peak I 6m, Peak II 12m

Ozone Access V6 6m, 4m incoming!

Arcs Venom 13m, Synergy 15m

LEIs Slingshot Rally 7m, 9, 12m

Kheo Flyer Landboard

PTW SuperBug II

Nobile NHP Carbon Split

|

|

|

PHREERIDER

Posting Freak

Posts: 5781

Registered: 13-2-2008

Location: SC

Member Is Offline

Mood: chilled....but ready to SAIL!

|

|

nice shot. drill and pin same size as bolts , find a good angle away from fixed weld .

clamp all together tight, right where you want it---> drill it small to large with it all clamped really can't mess it up. Don't let it slip!

simple easy effective , good stuff man

|

|

|

robinsonpr

Member

Posts: 351

Registered: 25-10-2014

Location: Stevenage UK

Member Is Offline

|

|

Don't fancy my chances of drilling that stainless...gonna need some proper hardcore pillar drill isn't it? And somehow get the frame into it!?

Rev 1.5 SLE

PL Pepper 1.5m, Twister III 3m

Flysurfer Peak I 6m, Peak II 12m

Ozone Access V6 6m, 4m incoming!

Arcs Venom 13m, Synergy 15m

LEIs Slingshot Rally 7m, 9, 12m

Kheo Flyer Landboard

PTW SuperBug II

Nobile NHP Carbon Split

|

|

|

Windstruck

Posting Freak

Posts: 3341

Registered: 16-5-2015

Location: St George, UT, USA

Member Is Offline

Mood: Get in my buggy!

|

|

Robinsonpr - pictures speak 1000 words. Great photos. I'd been waiting to weigh in to see them.

If you were American I'd now be saying "Whoa Cowboy"! Please put that drill bit away. Not saying all those excellent drill tips wouldn't do the trick,

but why go NUCLEAR before you've exhausted NEGOTIATIONS?

Now that we've seen the photos I bet I'm not alone in thinking of suggesting to you RedSky's thought voiced earlier in the thread and go VELCRO. Not

the flimsy stuff that you see on clothing, but the industrial strength stuff you can buy at a large hardware store. What I'm talking about can be seen

here: http://www.amazon.com/dp/B001O6T2ZS

This sort of Industrial-Strength VELCRO can be obtained in a near infinite variety of sizes and profiles (thickness). It comes as a sticky tape. I'd

want to buy it at a brick and mortar store versus online because if it were me I'd want to hold it in my hands to judge if it would fit in the space

that forms in between the outside of the axle and the inside of the clamp. Since the clamps bolt down I suspect there would be space to put something

such as this in there.

A further thought is I'd be putting the hooks on the axle and stuff the hooks connect with on the inside of the clamp. You will be dealing with a

"convex" surface issue on the axle and a "concave" issue on the inside of the clamp. I'd be examining the VELCRO to make sure the hook and pile sides

would still work being flexed into these convex and concave shapes and still intertwine properly for this fix to hold. If the hooks and what they hook

into can't lock in place then this design won't work and you'll have two slippery pieces of plastic tape in there and it will be more prone to

slippage than not having it in there at all.

It may well be that the super thick VELCRO I showed in the link is too much for this application and that some of their lighter grade material will

suffice (not all the way down to the flimsy stuff that holds a jacket cuff closed, but thinner than the maxed out stuff. VELCRO is INCREDIBLY strong

and is specifically designed not to shear once interconnected, exactly what you are looking for inside that clamp.

Good luck! We're all rooting for you. It is an absolutely beautiful buggy and we all want you enjoying it!

Born-Kites:

RaceStar+ (3.0m, 5.0m, 7.0m, 9.0m)

NasaStar-5 (2.5m, 4.0m)

NasaStar-4 (2.5m)

NasaStar-3 (3.2m)

Ozone kites:

Access (6.0m)

Flysurfer Kites:

Peak-5 (2.5m)

Buggy:

Peter Lynn BigFoot+ nose & tail; midsection VTT rail & seat kit; home-brewed AQR

NAPKA Member US2815

SWATK Member UT0003

|

|

|

PHREERIDER

Posting Freak

Posts: 5781

Registered: 13-2-2008

Location: SC

Member Is Offline

Mood: chilled....but ready to SAIL!

|

|

getting the set up in a press, that would be a difficult.

mark, punch it, fresh bits, keep it square with suitable pilot, then go with the finish size.

if the axle is solid, which would surprise me, could make things somewhat more challenging , a drill jig clamp would make things even easier and

indeed precise a bit overkill imho.

i would totally phree hand that, < 20MIN total. you could tap it if you liked, but i like quick pins, its fast easy tool free handling.

|

|

|

robinsonpr

Member

Posts: 351

Registered: 25-10-2014

Location: Stevenage UK

Member Is Offline

|

|

Thanks Steve! Yeah I deffo don't want to go nuclear before trying other options. Velcro will be my next try. Only thing is the OD of the axle is

very close to the ID of the clamps. I guess when it was built the intention was that nothing would be in between. Even with just a layer of thick

gaffa tape it was a real struggle to get the clamps closed enough to get the nut and bolt through.

I'll keep you posted once I've tried some of the other options!

Rev 1.5 SLE

PL Pepper 1.5m, Twister III 3m

Flysurfer Peak I 6m, Peak II 12m

Ozone Access V6 6m, 4m incoming!

Arcs Venom 13m, Synergy 15m

LEIs Slingshot Rally 7m, 9, 12m

Kheo Flyer Landboard

PTW SuperBug II

Nobile NHP Carbon Split

|

|

|

robinsonpr

Member

Posts: 351

Registered: 25-10-2014

Location: Stevenage UK

Member Is Offline

|

|

Phree! My phreehand is not as trained as yours. The axle isn't solid though, so maybe doable if the other options strike out!

Rev 1.5 SLE

PL Pepper 1.5m, Twister III 3m

Flysurfer Peak I 6m, Peak II 12m

Ozone Access V6 6m, 4m incoming!

Arcs Venom 13m, Synergy 15m

LEIs Slingshot Rally 7m, 9, 12m

Kheo Flyer Landboard

PTW SuperBug II

Nobile NHP Carbon Split

|

|

|

John Holgate

Posting Freak

Posts: 1512

Registered: 9-6-2009

Location: Australia

Member Is Offline

Mood: Cruising...

|

|

| Quote: |

Even with just a layer of thick gaffa tape it was a real struggle to get the clamps closed enough to get the nut and bolt through.

|

While you're at the hardware store grabbing some velcro, grab some longer bolts too. I'd hazard a guess that Pops has used stainless bolts, (unless

you mean you can't actually get the clamp close enough to line the holes up?) but there's no reason you couldn't grab some cheap zinc ones just as a

test.

Also, with the SS bolts/nuts, pop some sort of anti-seize on the threads before you do them up. I completely sheared the head off a brand new 8mm SS

bolt recently when the nut seized. In a pinch, a quick dip in some linseed oil seems to do the job.

|

|

|

Windstruck

Posting Freak

Posts: 3341

Registered: 16-5-2015

Location: St George, UT, USA

Member Is Offline

Mood: Get in my buggy!

|

|

:bisou:I was worried about that! If the fit is such that things are that tight (which doesn't surprise me or how would it hold) then I'd say two

things. First, consider longer bolts. Second, go with Phree and others that are suggesting drill-and-pin approaches. If hockey tape isn't fitting then

the Velcro certainly won't either.

(EDIT - John Holgate and I must have been typing at the same time. The advice changes if the bolt holes don't line up versus bolts too short. If they

don't line up then no bolt length change matters and, my friend, you're going NUCLEAR.)

Drilling is sort of like cutting wood. You can always go back and cut it shorter. Somewhere earlier was a suggestion to drill the same size as your

clamp's bolt holes. I'd start on the much smaller side in the hole department and drop a cotter pin through and clamp it down. The clamp must hold

back a lot of shear force, just not quite enough. I suspect even a small cotter pin would take you the rest of the way and not really sacrifice the

integrity of the axle. I'd hate to see you blast a giant hole through the axle to drop a bolt through. That would probably be thousands of times

larger than you need to get you locked in.

Born-Kites:

RaceStar+ (3.0m, 5.0m, 7.0m, 9.0m)

NasaStar-5 (2.5m, 4.0m)

NasaStar-4 (2.5m)

NasaStar-3 (3.2m)

Ozone kites:

Access (6.0m)

Flysurfer Kites:

Peak-5 (2.5m)

Buggy:

Peter Lynn BigFoot+ nose & tail; midsection VTT rail & seat kit; home-brewed AQR

NAPKA Member US2815

SWATK Member UT0003

|

|

|

3shot

Posting Freak

Posts: 2631

Registered: 14-2-2013

Location: Virginia

Member Is Offline

Mood: JIBE Talkin'

|

|

Agree with others. Drill and pin. Quality split point bits. Done..

You will just chase the issue with any other "sandwich" media. IMHO

Cross Kites Sonic 3, 5m

Ozone Flow 2, 3, 4, 5m

Ace II 4, 5m

NAPKA-US24

4, 5, 6m ATB landsurfer. Custom longboard deck

Buggy: VTT Black Widow v2.0

http://hint.fm/wind/

http://hint.fm/wind/

|

|

|

soliver

Posting Freak

Posts: 3913

Registered: 15-12-2011

Location: somewhere, far, far away

Member Is Offline

Mood: sleepy

|

|

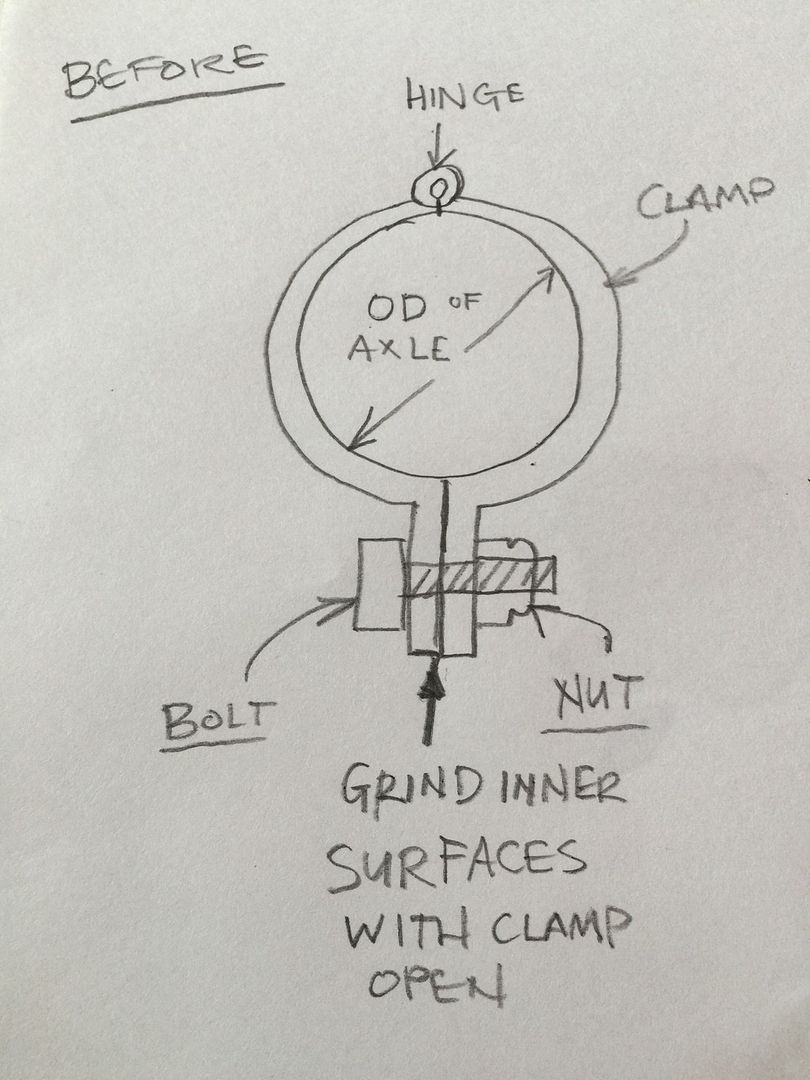

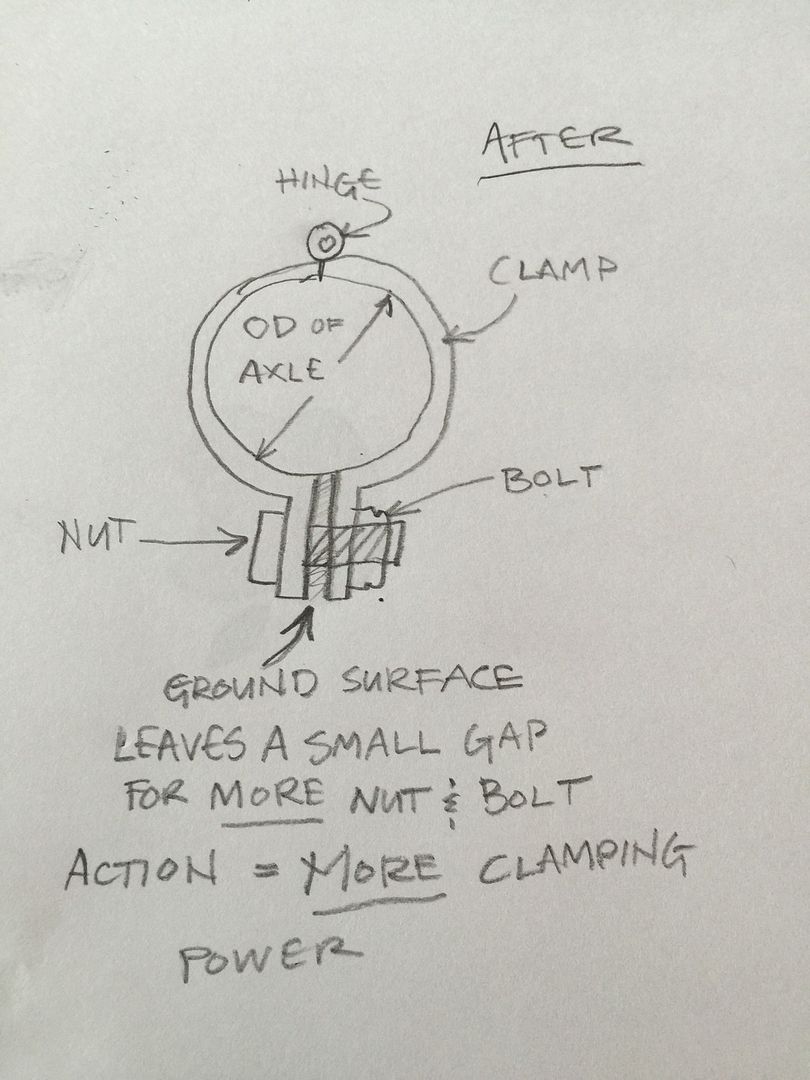

One option that hasn't been mentioned that I think may be worth considering is this,... if you grind the inside of the flat portion of the clamp (the

part where the bolt goes through), you will get more clamping power out of the nut/bolt/clamp combo by giving the clamp more room to close... if that

makes sense. I have done this fix to this style clamp (on a drill press ironically) and it did the trick.... I'll do an illustration and post it for a

visual... this would be doing the same job as ADDING something to the outer diameter of the axle, but may be more effective.

I think this would be a better fix than trying to drill... I think there are too many variables to that that may end up doing more damage than good...

I really think drilling the clamp and axle should be an absolute last option, and you might consider having it done by a metal fab shop.

I'm going to take a nap now

|

|

|

1oldkid

Member

Posts: 277

Registered: 19-10-2006

Location: Idaho

Member Is Offline

Mood: I gotta get me an avatar...

|

|

If you decide to drill, I would offer a suggestion:

Use a quality cutting fluid with the drills. I have used TapMagic and had good results. It will definitely help the drills cut...and you don't need a

lot.

Oh, and WEAR EYE PROTECTION!

Life's too short to be anything but happy!

My stuff:

Flexifoil 1.2m Sting

HQ Symphony 2.2m

Beamer 3.6m

Pro Foil 2.5, 4.5m

JoJo 6m

Montana 7m

Flysurfer 19m Speed 2 SA

Flexi bug

Several pair of kite skis

‘There are two types of education: One should teach us how to make a living, and the other should teach us how to live.’ - John Adams

|

|

|

soliver

Posting Freak

Posts: 3913

Registered: 15-12-2011

Location: somewhere, far, far away

Member Is Offline

Mood: sleepy

|

|

The idea is that by grinding the interior of the flat pieces that the bolts pass through, you are creating a small gap between them giving your

nut-bolt combo more room to move. Forgive the crudeness of the doodles... they are intended to be a cross section of the clamp. If its not obvious, by

grinding, I mean using an angle grinder and probably take off as little as 1/32 of an inch (or 1 mm)... just enough to create a small gap.

Before:

After:

I'm going to take a nap now

|

|

|

RedSky

Posting Freak

Posts: 1751

Registered: 7-9-2009

Member Is Offline

|

|

I hope drilling won't be necessary. We know Gaffer tape does work. Glen had about 10 sessions in total with this buggy without the axle slipping and I

know he won't mind me saying that he is 16st. I'm 14st and it never slipped once with me. He had problems at the beginning trying to prevent slippage

as you are now but he persevered. Getting the right tape thickness is crucial. Really tighten those nuts.

If you drill, then the idea of an infinitely adjustable axle is lost and I suspect it's resale value will diminish with it's single height setting. I

still think you'll have an easier time with the velcro. Two pieces squashed together between your thumbs takes up very little space.

|

|

|

Windstruck

Posting Freak

Posts: 3341

Registered: 16-5-2015

Location: St George, UT, USA

Member Is Offline

Mood: Get in my buggy!

|

|

As you go round and round with this problem one thing to keep in mind is that whatever you do please consider only doing it to ONE SIDE. I imagine you

are 95% of the way to the Promised Land with nut tightening with the original design. I would think there is 0% chance that the axle will turn on the

non-modified side once you successfully tape/Velcro/drill one side. For slippage to happen then you would need to spiral the axle along its long axis,

and that just isn't going to happen, no matter how many stones you're packin' downstairs!

Born-Kites:

RaceStar+ (3.0m, 5.0m, 7.0m, 9.0m)

NasaStar-5 (2.5m, 4.0m)

NasaStar-4 (2.5m)

NasaStar-3 (3.2m)

Ozone kites:

Access (6.0m)

Flysurfer Kites:

Peak-5 (2.5m)

Buggy:

Peter Lynn BigFoot+ nose & tail; midsection VTT rail & seat kit; home-brewed AQR

NAPKA Member US2815

SWATK Member UT0003

|

|

|

ColinW

Member

Posts: 243

Registered: 12-4-2015

Location: Victoria BC

Member Is Offline

|

|

I'm with soliver.

Get the clamps to go tighter, and then maybe try and get some longditudinal friction. Anything I've seen with this kind of joint usually has

lengthways grooves/stripes in the axle piece.

Even making something out of round would help.

I wouldn't want to drill the axle myself.

colin

p.s. I'm a carpenter and house builder, not an engineer nor a metal fabricator, so don't listen to a word I say.

|

|

|

soliver

Posting Freak

Posts: 3913

Registered: 15-12-2011

Location: somewhere, far, far away

Member Is Offline

Mood: sleepy

|

|

Thanks Colin, ... My idea is also presented under the assumption that there is no existing gap between the bolt plates on the clamp when they are on

the axle,... but IMHO logic would dictate that if you can tighten the clamp beyond the circumference or OD of the axle it shouldn't slip.

To me drilling it seems like a bad idea... I would also just be concerned about possibly weakening the integrity of the axle by drilling multiple

holes in the same area, not to mention the decreased value like RedSky was saying.

I'm going to take a nap now

|

|

|

robinsonpr

Member

Posts: 351

Registered: 25-10-2014

Location: Stevenage UK

Member Is Offline

|

|

Thanks again all!

And nice drawings Spencer!

The clamps don't quite meet when done up tight, so grinding for more leverage won't help. Nice suggestion though. Does beg the question could they

go tighter, but I know I would have only ended up stripping the thread.

Still a couple of options to try! As RedSky says, the previous owner managed to nail it with some tape and he is a much heavier unit than me!

I'm sure I'll get there one way or another! :D

Rev 1.5 SLE

PL Pepper 1.5m, Twister III 3m

Flysurfer Peak I 6m, Peak II 12m

Ozone Access V6 6m, 4m incoming!

Arcs Venom 13m, Synergy 15m

LEIs Slingshot Rally 7m, 9, 12m

Kheo Flyer Landboard

PTW SuperBug II

Nobile NHP Carbon Split

|

|

|

Kober

Posting Freak

Posts: 1942

Registered: 10-12-2010

Location: New Jersey

Member Is Offline

Mood: More kiting !!!

|

|

Sweet .....

New Jersey Kite Addicts

NAPKA US-212

2021 Eleveight FS .........10......12

2021 Eleveight XS .........14

Gin Zulu II / III .........5...7

Gin Sherpa .......10

Gin Yeti ..........4.5

Gin Tonkawa ..........3.1...4.1...5.4...6.8...8.7...11.5...15.4

Liquid Force ELITE .... 6m

Flysurfer Speed4 Lotus 18m

Flysurfer Sonic-FR .... 9 ....11....18m

Flysurfer Sonic2 .....11....15m

2016 Nobile Zen Hydrofoil with Infinity 5.1' splitboard

2019 Nobile 2HD with Ronix One boots

2020 Nobile NHP split foil with Ronix Parks boots

MG Supra ......... pulling KiteTrike

....... My videos!

|

|

|

| Pages:

1

2

3 |