tomdiving

Member

Posts: 410

Registered: 4-3-2017

Member Is Offline

Mood: thankful for this site

|

|

repairing a blown cell

grabbed a 3m scout to convert to handles. it worked rather well.

unfortunately, it had a blown cell that was not listed in the ebay sale. the previous owner runs a kite business and was unaware of this damage prior

to the sale.

would a simple tape repair be sufficient for this, or should all/part of it be sewn?

if the tape alone would be ok, can anyone recommend a good brand and/or supplier?

any tips on setting the kite up to get inside without taping everything together into a monstrous mess?

thanks!!!

tom

|

|

|

awindofchange

Posting Freak

Posts: 1945

Registered: 14-3-2006

Location: Salt Lake City, Utah

Member Is Offline

Mood: Awesome - totally awesome

|

|

The repair really depends on how serious it is and where it is located. If it is in the middle of the cell and less than 3-6 inches long, tape will

usually work and it will hold just fine. You want to lay the two pieces together so they mesh up perfectly, no overlap, then lay the tape down evenly

across the rip. Tape both the outside and the inside and round the corners of your tape and you should be good to go. Sometimes if it is really

difficult to get to and hold, you can use some 3m 77 spray adhesive on a piece of stiff cardboard, let it dry so that it is tacky to the touch. Then

tack the ripped material down on the cardboard to hold it in place. You can pull it off and re-position it as many times as needed. When both are

lined up then tape the other side, pull the cardboard off and put it on the taped area for support in taping the opposite side.

For tape, I highly recommend Prism's Tear-Aid repair tape. It is clear so it doesn't look like a Frankenstein repair on your kite and it works

excellent with ripstop material. To purchase use the link below.

http://www.awindofchange.com/product/pri-tearaid.html

If the repair is on a rib/skin seam then that is more difficult to do. Most times you will have to rip the seams (look up sewing seam rippers, don't

rip your kite open) on the kite to get it opened up so you can invert the kite to work on it (pull it inside out) usually the trailing edge is the

easiest to do, then use a strip of ripstop folded into an "L" shape and sew it onto the skin of the kite, then sew it onto the rib. Reinforcement

will need to be done to make sure the cell is the correct width and shape when inflated. If the cell is altered in dimensions it will adversely

effect how the kite flies and could cause loss of power or the kite to drift to one side or turn sluggishly in one direction or all the above. Once

done, re-sew the trailing edge closed and you should be good to go.

If the rib is torn or the tear in the skin is longer than 3-6 inches then you will most likely have to do the same as above but just use a piece of 2"

flat ripstop to patch the tear. Do this by sewing double seam all the way around the edge of the tear and then using a cross stitch seam across the

tear itself.

Note: For sewing repairs, be sure to use a good quality UV treated poly thread in either tex45 or tex70, do not use a cotton, nylon or woven thread

because it will stretch, breaks easy and will deteriorate under sun light.

After the repair is done and you have some loose fraying from the torn ripstop, you can fix that with some clear fingernail polish or some CA glue

dabbed onto the fraying areas.

Sometimes this can be a very time consuming job and can turn out to be quite difficult depending on how the kite is made. The kiteshop you purchased

the kite from should make good on this for you by replacing the kite for a good one.....or at least giving you one heck of a huge discount and refund.

Hope this helps.

|

|

|

Randy

Posting Freak

Posts: 1894

Registered: 20-5-2014

Member Is Offline

|

|

|

|

|

abkayak

Posting Freak

Posts: 2272

Registered: 7-1-2012

Location: a.b. NY

Member Is Offline

Mood: loving life and becoming wise in simplicity

|

|

NO.....a real blown cell isn't getting fixed w/ tape...3m kites flies into 30 mph winds

u can't tip toe w/ a kite under those conditions

that sale is unacceptable from a dealer or private seller

if u did impact the ground at all w/ it...well thats different

imo

US-31...Cquad set/ 2.5 Bullet/ 2.6 Viper/ 2.9m Reactor/ 2- 3.5m Bullet/ 3.6 Beamer/ 4m Buster/ 4m Toxic/ 4m Ikon dp/ 4.5 Bullet/ 4.9m Blade/ 5.6

Twister/ 6.6m Blade/ 7.5 Apex/ 9m Fuel/ Phantom I 9,12,15,18/ 2 Flexibugs/ PL Big Foot/ landboards

|

|

|

tomdiving

Member

Posts: 410

Registered: 4-3-2017

Member Is Offline

Mood: thankful for this site

|

|

great responses thus far.

no, I did not hit it into the ground at all. I never flew it on the bar. after switching it to handles, I doubt that it was in the air for 2 minutes.

I noticed a funky shadow when the kite had the sun in the background and landed it. that's when I saw the damaged rib. it is torn almost completely

from the leading to trailing edges.

the leading edge area has a couple of inches of original material holding it in place. everything else to the trailing edge is torn.

tom

|

|

|

jimbocz

Member

Posts: 224

Registered: 25-6-2010

Location: Twickenham, United Kigdom

Member Is Offline

|

|

I've had a few 3 meter kites that I bought knowing they had blown cells. The seem to fly just fine to me and I could never put my finger on any

practical way that it affected the way the kites flew. How did this kite fly?

Nonetheless, the kite is damaged in a way that wasn't declared by the seller so you are due a refund if you want. Or try to negotiate a partial

refund and keep the kite. I'm not sure I'd invest any money in paying for a professional repair unless the kite is otherwise especially valuable.

|

|

|

tomdiving

Member

Posts: 410

Registered: 4-3-2017

Member Is Offline

Mood: thankful for this site

|

|

jimbocz - interesting. it flies well. very well, in fact. my particular problem is that it was going to be used by more rookies, which will certainly

lead to more crashes.

the seller requested photos and is checking about a repair. he has said that if that will not be cost effective, he would gladly accept a return.

he's not trying to get away with anything.

the bargain hunter in me doesn't want to let a nice 3m kite for 160 dollars slip away.

I was hoping that the replies were more along the lines of "sure, slap some tape on it and it'll be fine."

obviously that's not the case.

I guess I'll just wait for the next response from the seller.

tom

|

|

|

tomdiving

Member

Posts: 410

Registered: 4-3-2017

Member Is Offline

Mood: thankful for this site

|

|

may take this project on myself

rereading windofchange's post, and trying to stick my head in the leading edge inlet (not quite, but it would have made a nice hat) to see the damage

better... I simply reached down inside, grabbed the trailing edge material, and pulled it inside out from there.

I have the entire bottom 20 inch ripped section out in the open. I think that I could make a serviceable repair to this section, stuff it back into

itself, and fairly easily get to the forward 16" or so section working on it from a normal outside position.

maybe clamp a couple of broomsticks to a step ladder to use as arms and slide the adjacent cells over the arms so I can get to everything somewhat

easily.

I'm still waiting to hear from the seller, but this is now a definite option.

tom

|

|

|

Randy

Posting Freak

Posts: 1894

Registered: 20-5-2014

Member Is Offline

|

|

I don't think you need to do all that with the ladders and so on. There is a technique called the "burrito roll" which you can use to do this sort of

repair. This link has some info on it and a link to a kitebuilder.com thread. I've used it a few times on kites I've built. The sewing can be hard,

but it does work.

NPW Test Pilot -US99

|

|

|

awindofchange

Posting Freak

Posts: 1945

Registered: 14-3-2006

Location: Salt Lake City, Utah

Member Is Offline

Mood: Awesome - totally awesome

|

|

Quote: Originally posted by tomdiving  | rereading windofchange's post, and trying to stick my head in the leading edge inlet (not quite, but it would have made a nice hat) to see the damage

better... I simply reached down inside, grabbed the trailing edge material, and pulled it inside out from there.

I have the entire bottom 20 inch ripped section out in the open. I think that I could make a serviceable repair to this section, stuff it back into

itself, and fairly easily get to the forward 16" or so section working on it from a normal outside position.

maybe clamp a couple of broomsticks to a step ladder to use as arms and slide the adjacent cells over the arms so I can get to everything somewhat

easily.

I'm still waiting to hear from the seller, but this is now a definite option.

tom |

It really depends on where the blown cell is located. Most of the time it is towards one end which is usually partially closed off or even fully

closed from the leading edge. If it happens to be right in the middle and the opening is wide enough then you can invert it from the leading edge and

get to it that way. It can be difficult to sew but may be easier than opening the kite up from the trailing edge.

|

|

|

tomdiving

Member

Posts: 410

Registered: 4-3-2017

Member Is Offline

Mood: thankful for this site

|

|

randy - I'm not seeing a link. i'll do a search for burrito roll.

kent - I guess I got lucky, if you can call it that. my blowout is on the rib at the "c" in "scout."

tom

|

|

|

Randy

Posting Freak

Posts: 1894

Registered: 20-5-2014

Member Is Offline

|

|

|

|

|

tomdiving

Member

Posts: 410

Registered: 4-3-2017

Member Is Offline

Mood: thankful for this site

|

|

getting professionally repaired

the seller is having me send it to Prokitesurf for a repair.

all is well now. I think it would have been fun to tackle as a project, but at the same time, I am glad that I don't have to.

thanks to all for contributing even more to my knowledge.

it looks like the burrito roll fix would be similar to what I was going to do to the trailing edge section, but with more tape and some hand

stitching here and there.

tom

|

|

|

PistolPete

Member

Posts: 279

Registered: 27-7-2010

Member Is Offline

|

|

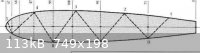

Looking for opinions on this repair before I start and make a mess. The victim here was a 19m Aurora1 that I took out in a light but gusty

day...result broken left center A and B bridle lines and looked inside to see a torn rib leading to trailing edge. Pulled kite inside out and took

photos of the ripped rib.

Repairs on the top and bottom skins seem simpler (than a rib repair) and are not used for high tension support areas. My concern is if this repair is

not strong enough it will rip out again. I think sewing a strip of rip stop on one side then sew another strip on the bottom side might be strong

enough?

I have used clear gorilla tape on LEI canopies which I think has a better adhesive than sail tape. The adhesive seems to be the weakest point, not

the backing material. But I don't think tape would be the best solution here. Ripstop sewn on ripstop might be the best. But I'm not sure of the

best sewing approach for this high tension seam. Below it is mentioned "...use a strip of ripstop folded into an "L" shape and sew it onto the skin

of the kite, then sew it onto the rib. Reinforcement will need to be done..." In my case the rib has enough material to be sewn and it is well

attached to the skin. So I am thinking about sewing the torn rib back together. Any description or photos of what the best seam to use might be?

Quote: Originally posted by awindofchange  | The repair really depends on how serious it is and where it is located. If it is in the middle of the cell and less than 3-6 inches long, tape will

usually work and it will hold just fine. You want to lay the two pieces together so they mesh up perfectly, no overlap, then lay the tape down evenly

across the rip. Tape both the outside and the inside and round the corners of your tape and you should be good to go. Sometimes if it is really

difficult to get to and hold, you can use some 3m 77 spray adhesive on a piece of stiff cardboard, let it dry so that it is tacky to the touch. Then

tack the ripped material down on the cardboard to hold it in place. You can pull it off and re-position it as many times as needed. When both are

lined up then tape the other side, pull the cardboard off and put it on the taped area for support in taping the opposite side.

For tape, I highly recommend Prism's Tear-Aid repair tape. It is clear so it doesn't look like a Frankenstein repair on your kite and it works

excellent with ripstop material. To purchase use the link below.

http://www.awindofchange.com/product/pri-tearaid.html

If the repair is on a rib/skin seam then that is more difficult to do. Most times you will have to rip the seams (look up sewing seam rippers, don't

rip your kite open) on the kite to get it opened up so you can invert the kite to work on it (pull it inside out) usually the trailing edge is the

easiest to do, then use a strip of ripstop folded into an "L" shape and sew it onto the skin of the kite, then sew it onto the rib. Reinforcement

will need to be done to make sure the cell is the correct width and shape when inflated. If the cell is altered in dimensions it will adversely

effect how the kite flies and could cause loss of power or the kite to drift to one side or turn sluggishly in one direction or all the above. Once

done, re-sew the trailing edge closed and you should be good to go.

If the rib is torn or the tear in the skin is longer than 3-6 inches then you will most likely have to do the same as above but just use a piece of 2"

flat ripstop to patch the tear. Do this by sewing double seam all the way around the edge of the tear and then using a cross stitch seam across the

tear itself.

Note: For sewing repairs, be sure to use a good quality UV treated poly thread in either tex45 or tex70, do not use a cotton, nylon or woven thread

because it will stretch, breaks easy and will deteriorate under sun light.

After the repair is done and you have some loose fraying from the torn ripstop, you can fix that with some clear fingernail polish or some CA glue

dabbed onto the fraying areas.

Sometimes this can be a very time consuming job and can turn out to be quite difficult depending on how the kite is made. The kiteshop you purchased

the kite from should make good on this for you by replacing the kite for a good one.....or at least giving you one heck of a huge discount and refund.

Hope this helps. |

NAPKA-US28

|

|

|

Randy

Posting Freak

Posts: 1894

Registered: 20-5-2014

Member Is Offline

|

|

I'd send it to fixmykite.com or least send them the pictures and see what they would charge to fix it. I've heard they do this sort of thing at a

very reasonable price. Of course there is shipping both ways, so it might be expensive.

If that is not something you want to do, can you just remove the rib and make a new one out of ripstop? I almost think you have to remove it anyway

to just do the repair you are thinking of. The burrito roll method doesn't have to be performed using the last cell on a side - I've done it at the

middle cell, doing one side of the wing and then the other on other foil kites I built. It is actually easier that way. Also repaired a blown cell

on kite I got on ebay which was about 1/3 the way from the end cell.

NPW Test Pilot -US99

|

|

|

Chook

Member

Posts: 141

Registered: 25-10-2009

Location: Esperance Western Australia

Member Is Offline

Mood: I work at home from 8.00am to 12 knots

|

|

Glad it's sorted out.

It's lucky that the tear is easily accessible through the leading edge.

If not then a hard heart is needed and unpick the trailing edge each side of the damaged cell.

The tacky cardboard idea is a huge help. I use thin 1/16" flexible kitchen plastic cutting boards, (cut to lots of shapes as needed) and lightly

sprayed with 3m 77. It's a life saver when the ripstop is frayed/torn out of shape. Take your time refitting it together using the fabrics natural

grid pattern for a reference and it will knit back into place perfectly.

It is really important to create "index marks" every 6" or so (pencil lines on cell wall and skin intersection) as you unpick a cell to skin stitch

line, so that it is reassembles correctly and skin patterns align properly. This ensures the kite performs as it did originally.

Most repairs are not that difficult, but as Kent indicated they can certainly run away with a lot of time and not something to do when your in a

hurry. I "triple stitch zig-zag" around the outside of every patch (with it's corners rounded off) as in our hot weather they tent to lift off over

time and then attract grit.

I get a lot of satisfaction out of doing my own repairs and getting them back into the air. I have bought a lot of damaged/cheaper kites over the

years and repair them in the air-conditioning when it's too hot to go outside. Some of these damaged purchases would have been totally uneconomically

viable to have be professionally repaired, but they live to fly again.

One 13m2 foil power kite I bought was in 3 bits when it arrived, (pulled down out of a high tree without any care) but this was reflected in the dirt

cheap purchase price and it flew perfectly after the repairs.

Modified Sysmic S2 Buggys

7m R1

8m R1 2

11m R1

15m R1

15m Chrono 2

18m Chrono

18m ELF

|

|

|

PistolPete

Member

Posts: 279

Registered: 27-7-2010

Member Is Offline

|

|

Thanks Randy,

Plan to do the repairs myself.

Thanks Chook,

Good tips to know. For this on I think I'll tape then sew ripstop down the tear then add a few straps across the holes to increase strength (repair

fabric shown in red).

NAPKA-US28

|

|

|

Randy

Posting Freak

Posts: 1894

Registered: 20-5-2014

Member Is Offline

|

|

Another option would be to sew a reinforcement line zig zag around the vent holes. Either way probably is fine - it would just be up to you to decide

which is easier.

NPW Test Pilot -US99

|

|

|

PistolPete

Member

Posts: 279

Registered: 27-7-2010

Member Is Offline

|

|

Success :bouncy:

Test flew my rib & bridle repair last night then took a look inside to verify my repair is still structurally sound.

Repair was not too difficult but requires patience. Could only machine sew a few places. Hand sewing was easier and quicker in tight places. I

found 2 other small tears to adjacent ribs towards the leading edge that I also fixed. I now understand the method mentioned above "use a strip

of ripstop folded into an "L" shape and sew it onto the skin of the kite, then sew it onto the rib", this works great. My repairs only required

a small amount of new fabric and when completed, repaired areas were stronger that the original fabric in those areas. No need to cross-brace the rib

holes for super strength...

I landed the kite a few times in my test flight and used the 5th line. I think the greatest rib stress is where the 5th line attaches... Because

the location of the tear was to one side, near where the center-left A & B bridles broke... the bridles probably broke first then the

extra/unusual strain on the nearby ribs ripped. Maybe the bridles broke because of loading or they were compromised/nicked/cut when I was landing or

launching.

NAPKA-US28

|

|

|

ColinW

Member

Posts: 243

Registered: 12-4-2015

Location: Victoria BC

Member Is Offline

|

|

Well done!

I pulled out our (my wife's) sewing machine to fix a leading edge seam in one of my revs the other day.

Ripstop is slippery.

Sewing machines are fast.

Swiss cheese anyone?

What kind of thread did you use? I am hearing polyester for uv resitance, but any thoughts from anybody on weight/thickness of thread?

I bought some polyester outdoor upholstery thread from a local sewing store. It worked for the job, but was much thicker than the original.

Maybe Randy or Riffclown can cjime in here? Thew quilting types at the sewing center were friendly but not much help.

I also hear there are glues that can be used instead of pins to hold stuff together until the sewing is done, but can't figure out what kind.

|

|

|

Randy

Posting Freak

Posts: 1894

Registered: 20-5-2014

Member Is Offline

|

|

I just use 100% polyester thread, the kind they sell at Walmart. Coates and Clark dual duty is what I usually get. It is pretty light thread but

when I used heavier threads they got bogged down in my machine. I've can't think of a thread failure I've had. Usually problems I've had were due to

my poor stitching, choice of materials or something similar. Single skin kites are what I usually make, so they are not prone to damage like a foil

though. I recall once the "nose scrunch" attachments on an NPW failed - but it was because the fabric ripped, not the thread.

NPW Test Pilot -US99

|

|

|

ColinW

Member

Posts: 243

Registered: 12-4-2015

Location: Victoria BC

Member Is Offline

|

|

Thanks for that Randy. Exactly the kind of first hand expert info I was after.

|

|

|