riffclown

Posting Freak

Posts: 1101

Registered: 8-7-2013

Location: Virginia

Member Is Offline

Mood: rain rain go away...leave some wind so I can play.

|

|

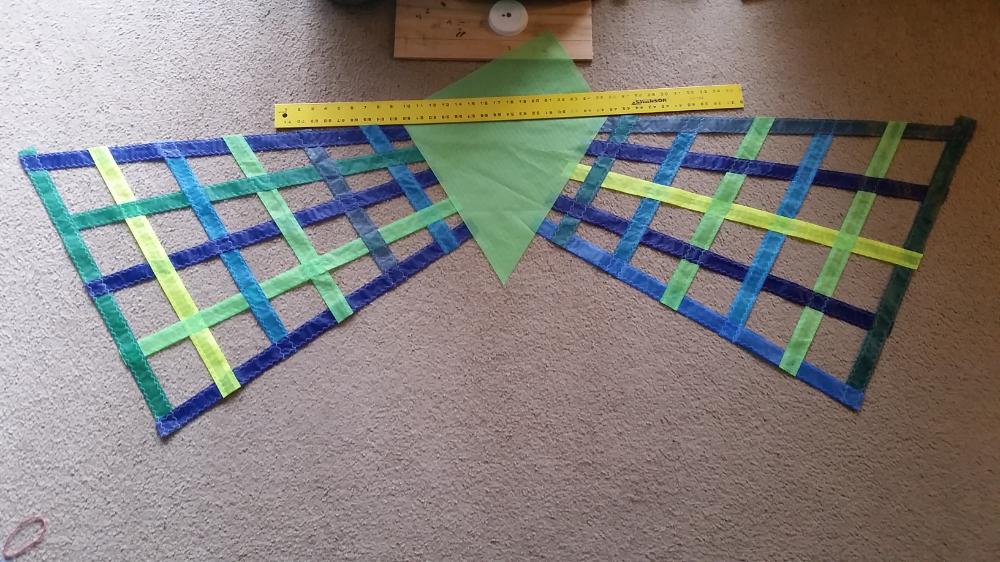

Started another one today

Calling it "Hope of Spring"..

|

|

|

Randy

Posting Freak

Posts: 1893

Registered: 20-5-2014

Member Is Offline

|

|

Looks like you are off to a good start!

NPW Test Pilot -US99

|

|

|

riffclown

Posting Freak

Posts: 1101

Registered: 8-7-2013

Location: Virginia

Member Is Offline

Mood: rain rain go away...leave some wind so I can play.

|

|

Trying to design the center section today..

|

|

|

riffclown

Posting Freak

Posts: 1101

Registered: 8-7-2013

Location: Virginia

Member Is Offline

Mood: rain rain go away...leave some wind so I can play.

|

|

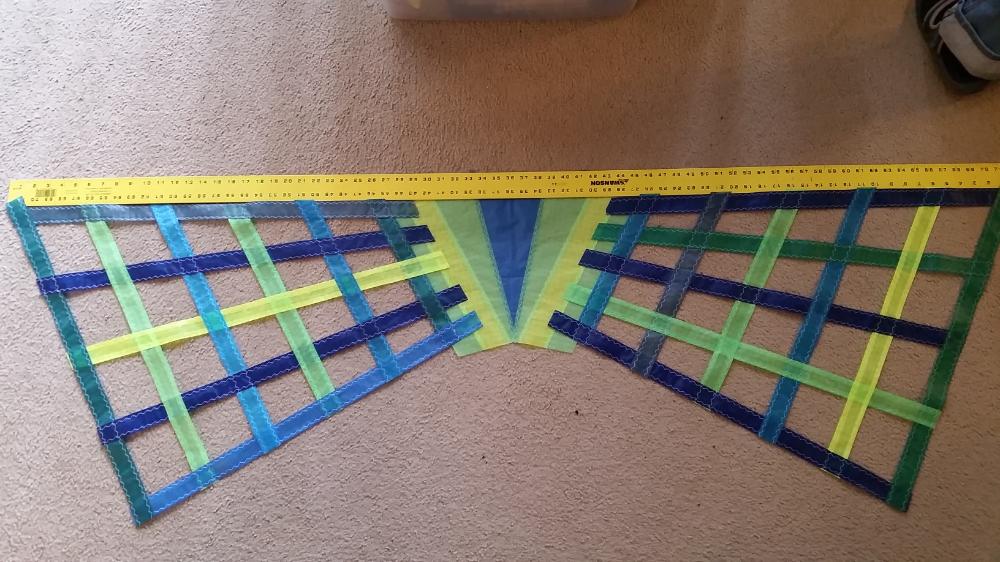

Center Design is complete. Now to start assembly.

|

|

|

riffclown

Posting Freak

Posts: 1101

Registered: 8-7-2013

Location: Virginia

Member Is Offline

Mood: rain rain go away...leave some wind so I can play.

|

|

Decided to go ahead and make the LE to compliment the same Spring Colors.

.

|

|

|

riffclown

Posting Freak

Posts: 1101

Registered: 8-7-2013

Location: Virginia

Member Is Offline

Mood: rain rain go away...leave some wind so I can play.

|

|

Bridle test went well. Waiting for Wind!!!

|

|

|

Randy

Posting Freak

Posts: 1893

Registered: 20-5-2014

Member Is Offline

|

|

That was quick. Like 3 days......And that is a complicated mesh job.

NPW Test Pilot -US99

|

|

|

riffclown

Posting Freak

Posts: 1101

Registered: 8-7-2013

Location: Virginia

Member Is Offline

Mood: rain rain go away...leave some wind so I can play.

|

|

It's a smaller kite (72") and the vertical-ish strips are parallel..

Another thing that sped this up a lot was I had the strips already creased and pressed from the last 3 builds so it was almost all pre-folded scraps.

Still learning ways to make this a quicker process though..

|

|

|

tomdiving

Member

Posts: 410

Registered: 4-3-2017

Member Is Offline

Mood: thankful for this site

|

|

ok, here's me knowing absolutely zero about making kites or prepping material to make kites...

how do you set the crease in the strips before rolling them in the paper? would a clothes iron help with that? if i wanted a 1" strip, what if i put

a 2" width of material down on top of a length of stainless steel, aluminum, etc. (a metal yardstick, perhaps? then fold the edges of the cloth from

underneath, over the top of the metal, and then just iron that?

what about clamping multiple strips on a piece of plywood or something and then putting that in one of these - https://duckduckgo.com/?t=ffnt&q=pants+steam+press&a...

if that sets and holds a crease, you'd save the day or two of leaving strips in a roll of paper.

i do not have any idea of how the material you're working with may react to the heat of the iron. maybe it does nothing, maybe it does help set an

edge.

how about an old double-roller setup like an (really) old clothes wringer? start the crease, and just roll it through with the handle. - https://duckduckgo.com/?q=clothes+wringer+&t=ffnt&at...

perhaps running the clothes iron over the material while it's in your paper roll?

if you're using a spray glue, then i guess none of this would matter.

just thinking.

tom

|

|

|

riffclown

Posting Freak

Posts: 1101

Registered: 8-7-2013

Location: Virginia

Member Is Offline

Mood: rain rain go away...leave some wind so I can play.

|

|

FWIW I don't use glue, tape or heat to make or set the folds. Heat contracts the fabric a bit and then with only a small increase in heat will melt

it quickly after so that is a non-starter for me. The two temps between "help" and "disaster" are too close for my comfort.

I use a straight edge to help make the crease.. I then set the crease by sliding it over the edge of a board or table and finally use the pressure

from the roll of paper to set and flatten the crease. Getting it straight on the longer folds and being consistent is the more difficult parts of the

process.

Incidentally, +/- 1/16" is generally ok but +/- 1/8" starts to get pretty noticeable.

|

|

|